Residential Epoxy Flooring

Residential Epoxy Flooring in the South Carolina Lowcountry

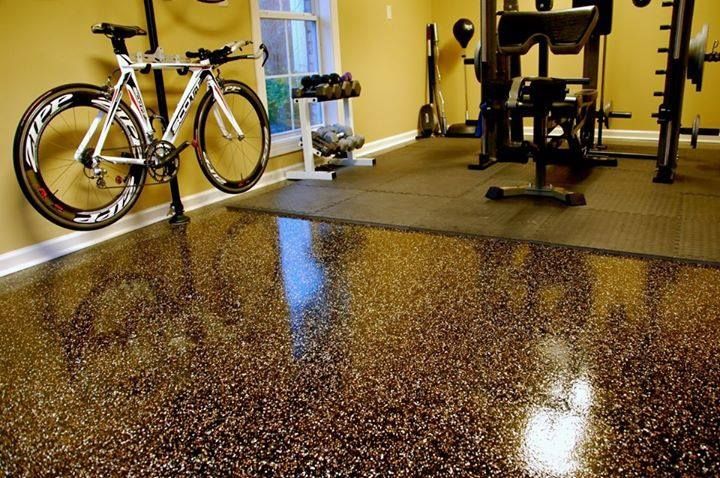

Transform Your Home with Professional Epoxy Floor Coatings

Your home deserves flooring that works as hard as it looks beautiful. Whether you’re upgrading your garage, finishing your basement, or creating stunning outdoor living spaces, professional epoxy flooring delivers the perfect blend of durability and design—without the premium price tag you’d expect from luxury renovations.

Galaxy Epoxy Coatings brings professional-grade flooring solutions to homeowners throughout the South Carolina Lowcountry, from Hilton Head to Charleston. As a veteran-owned local business trained at the Liquid School of Epoxy, we’ve built our reputation on honest pricing, superior craftsmanship, and floors that truly last.

Why Homeowners Choose Epoxy Flooring

Unmatched Durability for Real Life

Life happens—spilled drinks, dropped tools, hot tires, constant foot traffic. Your floors take a beating every single day. Standard concrete stains, cracks, and looks worse with every passing year. Paint chips within months. Tiles crack and grout lines trap dirt and moisture.

Epoxy flooring creates a resilient, impact-resistant surface that stands up to everything your family throws at it. The chemical bonding process creates a seamless protective layer that’s stronger than the concrete beneath it. You’re not just covering your floor—you’re reinforcing it.

Real-world performance:

Stunning Designs That Reflect Your Style

Gone are the days when epoxy meant boring gray industrial flooring. Today’s residential epoxy systems offer unlimited aesthetic possibilities, from subtle elegance to bold statements.

Popular finish options:

Each system can be customized with your choice of gloss level—from high-shine reflective finishes that brighten spaces to practical matte or satin sheens that hide imperfections and reduce glare.

Effortless Maintenance That Saves Time and Money

Weekends are for living, not scrubbing floors. Epoxy’s seamless, non-porous surface means dirt, dust, and spills sit on top instead of soaking in. No grout lines to harbor mold. No porous concrete absorbing oil stains. No cracks collecting debris.

Simple cleaning routine:

The smooth surface reflects light back into your space, making garages, basements, and patios feel brighter and more inviting without adding a single fixture. This light-enhancing quality transforms dark, dungeon-like spaces into functional, welcoming areas your family actually wants to use.

Chemical and Stain Resistance You Can Count On

Automotive fluids, garden chemicals, household cleaners, pet accidents—your floors face constant exposure to substances that ruin traditional flooring. Epoxy’s chemical-resistant surface repels these contaminants instead of absorbing them.

Oil changes, battery acid, fertilizers, paint spills, salt from winter boots, cleaning products, even hot barbecue grease—none of these will permanently stain or damage a properly installed epoxy floor. This protection extends the life of your concrete substrate while keeping your space looking pristine.

Moisture Protection for Humid Lowcountry Climate

Living in the South Carolina Lowcountry means dealing with humidity, moisture, and the occasional flooding event. Standard concrete absorbs water, leading to:

Epoxy’s seamless, waterproof barrier prevents moisture penetration, protecting both the coating and the concrete underneath. This is especially critical for basement applications where moisture mitigation is essential, and outdoor patios exposed to rain and sprinkler systems.

Safety Features Built In

Slippery garage floors become hazardous when wet. Smooth concrete offers little traction. Epoxy systems can be customized with slip-resistant additives that provide grip without compromising appearance. This is particularly important for:

The textured finish of flake systems naturally provides excellent slip resistance, while smooth metallic or solid color systems can incorporate additives for additional safety.

Increase Your Home’s Value and Appeal

Smart homeowners know that strategic improvements yield returns when it’s time to sell. While epoxy flooring may not add dollar-for-dollar value like a kitchen remodel, it significantly enhances your home’s appeal to potential buyers by:

A beautifully finished garage or basement signals quality throughout the property. Buyers notice—and remember—these thoughtful upgrades.

Where Residential Epoxy Flooring Excels

Garages: From Storage Space to Showroom

Your garage deserves better than cracked, stained concrete that looks worse every year. It’s likely one of the largest rooms in your home and often the first space you see when arriving home. Make it count.

Garage floor benefits:

Whether you’re a car enthusiast wanting a showroom-quality space, a DIY hobbyist needing a functional workshop, or simply tired of looking at ugly concrete, garage epoxy flooring delivers immediate impact.

Basements: Comfortable, Moisture-Resistant Living Space

Basements in the Lowcountry face unique challenges—humidity, occasional moisture intrusion, and the need to create comfortable living spaces below grade. Epoxy solves these problems while opening up design possibilities.

Basement applications:

Unlike carpet that harbors mold and allergens, or tile that cracks and allows moisture through grout lines, epoxy creates a seamless moisture barrier that’s comfortable underfoot and easy to maintain. The variety of finishes means your basement floor can match any décor—from cozy and traditional to sleek and modern.

Patios and Outdoor Living: Beautiful, Weather-Resistant Surfaces

Coastal living means outdoor entertaining year-round. Your patio should be as beautiful and functional as your interior spaces, but traditional options fall short:

Epoxy coating over properly prepared concrete patios provides:

Create the outdoor oasis you’ve always wanted without the maintenance headaches of traditional materials.

Sunrooms, Pool Houses, and Specialty Spaces

The versatility of epoxy makes it ideal for unique applications throughout your home:

Anywhere you need a combination of beauty, durability, and easy maintenance, epoxy delivers.

Kitchen Floors: Yes, Really

Progressive homeowners are discovering that residential-grade epoxy isn’t just for garages. When properly installed with food-safe, low-VOC products, epoxy creates stunning, highly functional kitchen floors that rival any traditional option:

While less common than garage and basement applications, kitchen epoxy flooring represents the cutting edge of residential design—combining industrial performance with residential aesthetics.

The Galaxy Epoxy Process: What to Expect

Initial Consultation (Free)

Every great floor starts with understanding your vision, needs, and space. During your free consultation, we:

This onsite assessment is crucial because no two floors are exactly alike. Existing damage, moisture levels, and intended use all influence which system will deliver the best long-term results.

Surface Preparation: The Foundation of Success

Professional preparation separates floors that last decades from DIY disasters that fail within months. We use mechanical diamond grinding to:

This process is time-consuming and requires specialized equipment, but it’s absolutely non-negotiable. The coating is only as good as the surface beneath it. We won’t compromise on prep work—it’s where most failures originate.

For moisture-prone areas, we conduct thorough moisture testing and may install moisture mitigation primers to prevent future issues. Ignoring moisture is the leading cause of coating failure in the Lowcountry’s humid climate.

Professional Application

Once prep is complete, we install your chosen system:

Each layer requires specific mixing, application techniques, and curing time. Factors like temperature, humidity, and the coating’s pot life all affect the process. This is why professional installation matters—the chemistry must happen correctly, at the right time, under the right conditions.

Timeline for Most Residential Projects

Typical single-car garage or small patio: 1-2 days

Larger projects (2-3 car garages, full basements): 2-3 days

Walk-on time: 6-24 hours after final coat Full cure for heavy use: 3-5 days before vehicle traffic.

Weather, temperature, humidity, and specific product choices affect timelines. We provide realistic schedules during planning and communicate clearly throughout the process.

DIY Epoxy Kits vs. Professional Installation

Hardware store epoxy kits are tempting—they seem affordable and promise professional results. The reality is disappointingly different.

Why DIY Kits Usually Fail

The True Cost of DIY Failures

When DIY epoxy fails—and it usually does within 6-18 months—you face expensive removal and remediation:

Many of our clients come to us after DIY disasters. We’re always happy to fix these situations and deliver the lasting floor you deserved from the start. But it’s far more economical to invest in professional installation initially.

Our Restoration Approach for Failed DIY Projects

We understand the frustration of a DIY project gone wrong. Our approach to fixing failed epoxy is:

Turning a disappointing DIY attempt into a beautiful, lasting floor is something we take pride in. You shouldn’t have to live with a mistake when professional solutions are available.

Choosing the Right Epoxy System for Your Home

Factors That Influence System Selection

Intended use and traffic levels:

Environmental conditions:

Aesthetic preferences:

Budget considerations: We offer multiple system levels so you can choose the best fit for your needs and budget:

Product Selection: Quality Without Compromise

We predominantly use Rust-Oleum products—industry-trusted, lab-tested systems with proven performance. Depending on your specific application, we may utilize:

We select the highest quality materials at the best price point for each application. You get professional-grade products without paying retail markups.

Maintenance and Longevity

Stop living with a failed floor. Get a professional assessment and honest solution.

When to Consider Recoating

Not every floor needs complete replacement. Lightly worn floors installed correctly can often be refreshed with just a new topcoat, saving time and money. Deep damage, contamination, or failing coatings require more extensive work.

We always start with an honest onsite assessment to determine whether simple maintenance or full recoating will give you the best long-term value.

Keeping Your Floor Beautiful for Decades

Proper maintenance extends the life of your epoxy floor and keeps it looking new:

Daily/Weekly Care:

- Sweep or vacuum to remove loose dirt and debris

- Damp mop with pH-neutral cleaner or mild soap

- Wipe up spills promptly (though most won’t stain even if left)

What to Avoid:

- Abrasive scrubbing pads that can scratch the surface

- Harsh chemical cleaners (though epoxy resists these well)

- Soap-based products that leave residue and reduce gloss

Long-term Maintenance: Properly installed residential epoxy requires minimal long-term maintenance. No waxing, resealing, or refinishing is necessary for 15-20 years. In high-traffic areas, you may eventually want to refresh the topcoat, but the base system remains intact.

Pricing and Investment

Transparent Pricing You Can Trust

We believe in complete transparency—no hidden fees, no surprises, no pressure tactics. Our pricing reflects:

Typical residential project ranges:

Aesthetic preferences:

Every project starts with a free consultation where we walk through options and provide detailed, written estimates. In many cases, we can offer multiple quotes for the same project with different system types, giving you flexibility to choose what works best for your needs and budget.

What Affects Your Project Cost?

Surface condition: Extensive cracking, damage, or previous coatings increase prep time Moisture issues: May require additional moisture mitigation steps Premium finishes: Metallic systems and custom designs cost more than standard flake Access challenges: Difficult access or furniture moving adds labor time Repairs needed: Fixing structural issues before coating increases overall cost.

We can’t control supplier costs, but we shop around to keep our pricing fair and competitive. As a local, veteran-owned business operating with integrity, our goal is to deliver exceptional value—not to be the cheapest option, but to be the best investment.

Financing Options

We’re working to implement financing options to make professional epoxy flooring more accessible to homeowners throughout the Lowcountry. Contact us for current availability.

Why Choose Galaxy Epoxy Coatings?

Veteran-Owned, Locally Operated

As a veteran-owned business, we bring military values to every project: integrity, attention to detail, mission focus, and commitment to excellence. We live and work in the Lowcountry community we serve.

Professional Training and Certification

We’re graduates of the Liquid School of Epoxy—professional training that sets us apart from competitors who learned through trial and error. This education ensures we understand the chemistry, application techniques, and problem-solving required for lasting results.

Honest, Ethical Pricing

We provide fair quotes that reflect the actual scope of work—not artificially low bids that require expensive change orders later. Transparent pricing means you’ll know exactly what materials cost and what you’re paying for.

Quality Materials, Expert Installation

We use only the highest quality professional-grade products, applied by trained personnel who understand proper mixing, application, and curing. The combination of premium materials and expert installation ensures floors that perform as promised.

Our Guarantee

If you don’t like our work, we’ll make it right. That’s our commitment. Beyond that, we offer warranties covering adhesion, peeling, and product performance. Exact terms vary by system and manufacturer, but we’re always clear up front about what’s included so you can invest with confidence.

Ready to Transform Your Space?

Stop living with ugly, stained, cracking concrete. Professional epoxy flooring delivers the durability, beauty, and easy maintenance your home deserves—at a price that makes sense.

Your next steps:

Serving the entire South Carolina Lowcountry: Hilton Head Island • Bluffton • Beaufort • Port Royal • Hardeeville • Ridgeland • Charleston area • And surrounding communities

Ready to Get Started?

📞 Call or text us today for your free consultation 📧 Email us your project details 📅 Schedule online at your convenience

Galaxy Epoxy Coatings • Veteran-Owned • Licensed & Insured • Serving the Lowcountry with Pride. Let’s create a floor you’ll love for decades to come.

Ready to transform your floor?

Contact us today to schedule your free estimate.